Item | Specification | Remark |

|---|---|---|

Table Size | (W)300mm x (D)600mm | |

Target Size | Small size~15inch | Flat and Curved (Assumption: R500~ R1000) |

Coating Thickness | 50µm-800µm | Value with Flat Surface |

Coating Thickness Accuracy | 50µm-100µm: ±10µm 100µm-800µm:±10% | Value with Flat Surface Value with Flat Surface |

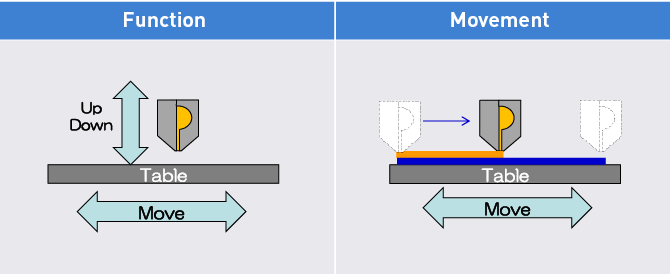

Slit Nozzle Coating Width | Max: 200mm | |

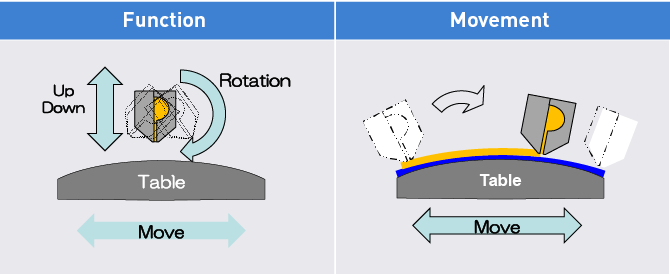

Slit Nozzle Mobility Width | Mobility range: ±30° (Equivalent to R500) | |

Work Piece Suction Method | Vacuum | |

Workable Viscosity | 1000~150000mPa・s |

Item | Specification | Remark |

|---|---|---|

Table Size | (W)300mm x (D)600mm | |

Target Size | Small size~15inch | Flat and Curved (Assumption: R500~ R1000) |

Coating Thickness | 50µm-800µm | Value with Flat Surface |

Coating Thickness Accuracy | 50µm-100µm: ±10µm 100µm-800µm:±10% | Value with Flat Surface Value with Flat Surface |

Slit Die Coating Width | Variable width: 100~200mm | Extensible |

Slit Die Swing area | Swing range: ±30° (Equivalent to R500) | |

Work Piece Suction Method | Vacuum | |

Workable Viscosity | 1000~150000mPa・s |

Item | Specification | Remark |

|---|---|---|

Coating width | 100~200mm | Extension available |

Resin thickness | 50μm-800μm | |

Resin thickness precision | 50μm-100μm: ±10μm 100μm-800μm: ±10% | |

Available viscosity | 1,000~15,000mPa・s |

Task | In case of using each head matching the model | In case of using Multi-Device Slit Coater |

|---|---|---|

Removal of head | 4min | No need |

Disassemble of head and cleaning | No need | No need |

Re-assemble of head (Exchange of shim) | No need | No need |

Set up of head | 5min | No need |

Replacementand degas of resin | 5min It’s necessary in advance to refill the resin in the replaced head | No need |

GAP Confirmationand adjustment of GAP | 3min | No need |

Change of operation recipe | Recipes are automatically switched based on model information from external devices such as barcodese | Recipes are automatically switched based on model information from external devices such as barcodes |

Confirmation of coating conditions | 5min (It depends on the items to confirm) | 5min (It depends on the items to confirm) |

Total | 22min (*) | 5min |

| Item | Specifications | Remark | |

|---|---|---|---|

| Machine size | W1200 x L1550 x H2000, 800kg | ||

| Utility | AC200-220, 3Φ, 30A, CDA (Clean Dry Air), Vacuum | CDA(for resin feed ) Vacuum(for Chucking) | |

| Substrate | Max 420mm x 300mm x t0.5-20mm | ||

| Unit | Slit die | Width: Max. 400mm | |

| Stage drive | By servo motor, speed control: 3-400mm/sec | ||

| Resin pump | Gear Pump: Viscosity: max 6,000cp | (Option) Heishin pump (Viscosity max 1,000,000cp) |

|

| Cleaning Unit | Roller Type | ||

| Gap Control | Gap Control by substrate thickness sensor | ||

| Coating spec. | Thickness | 50~300um (Value recorded by machine supplier) | |

| Uniformity | +/-10%(Value recorded by machine supplier) | ||

| UV-Cure | LED Type, 405nm, L400mm (Loctite 97668, x5set) | ||

| Resin supply | Tank x2 | ||

| Ctrl, Mam-Machine Interface | PLC, Touch panel | ||

| Coating condition setting | * Start point:Gap, Speed, Resin feeding volume, timing * Middle point:Gap, Speed, Resin feeding volume * End point:Gap, Speed, Resin feeding volume, | ||